Power Generation Solutions for Ceramic Production

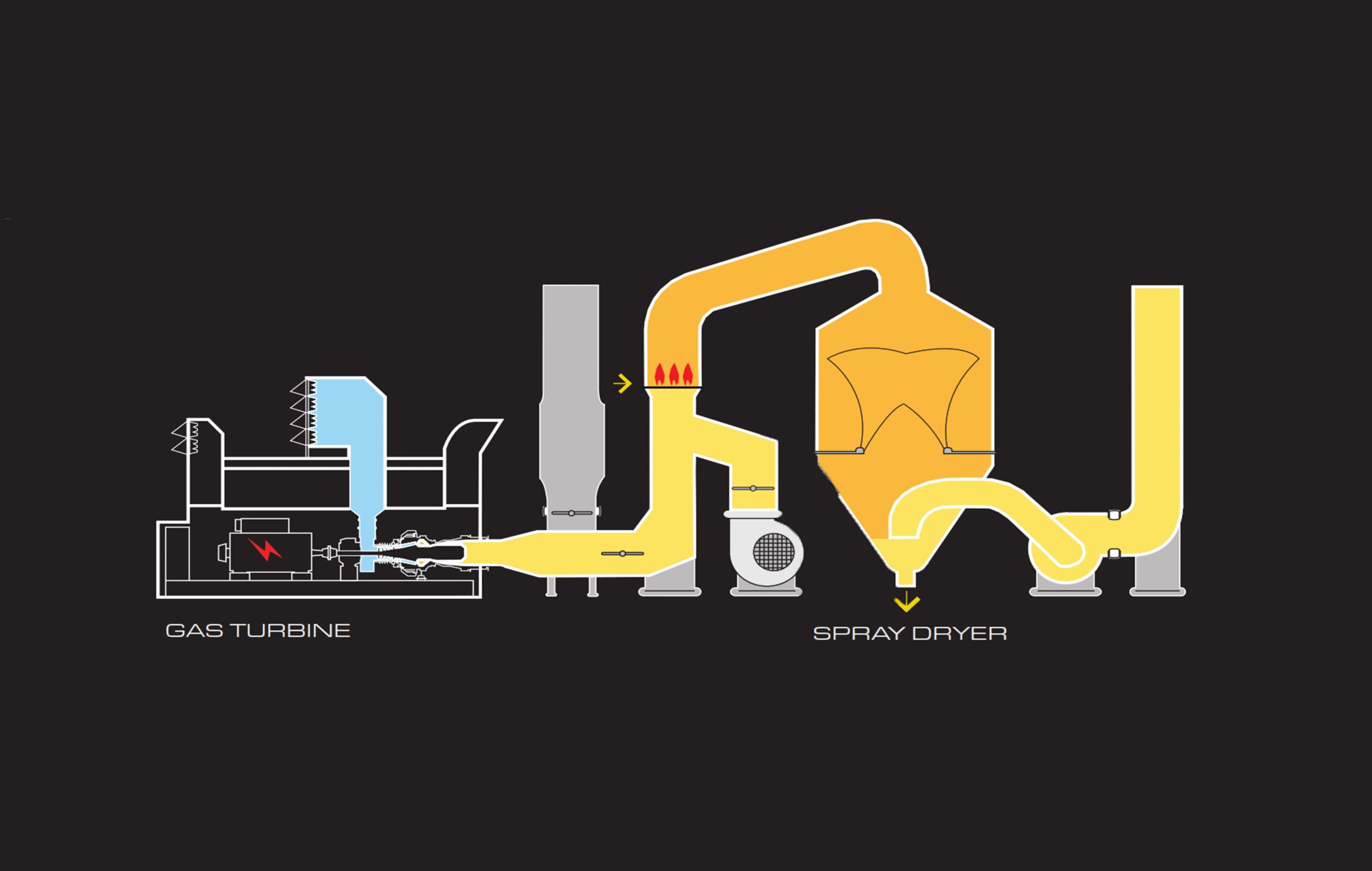

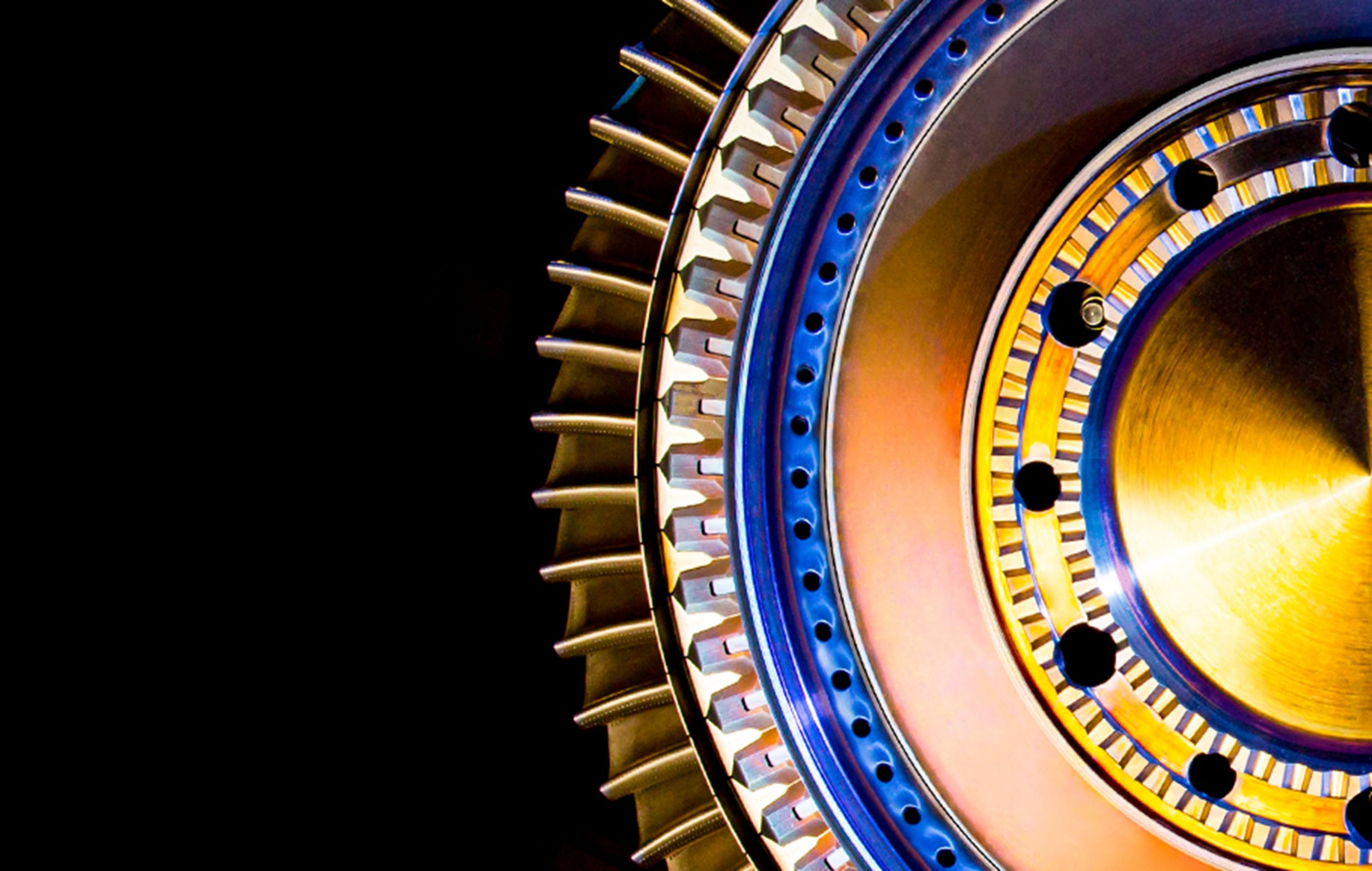

The ceramic industry demands enormous amounts of energy for the drying processes of various material, including clay, glass, brick, tiles and fixtures. The best way to improve the efficiency of ceramic manufacturing is to connect a gas turbine to the spray dryer, providing heat along with electrical power for the facility.

Efficiency and Cost Savings for your Plant

Solar uses gas turbine-based cogeneration, better known as Combined Heat and Power (CHP). Solar’s cogeneration ceramic application process uses gas turbine exhaust air in the ceramic spray dryer by bringing high quantity heat into the drying process. A gas turbine connected to a spray dryer increases the process efficiency from 27-32% to 75-90% and saves on electrical and fuel costs in the ceramic industry. Cogeneration in ceramic application provides simultaneous and independent generation of power and heat.

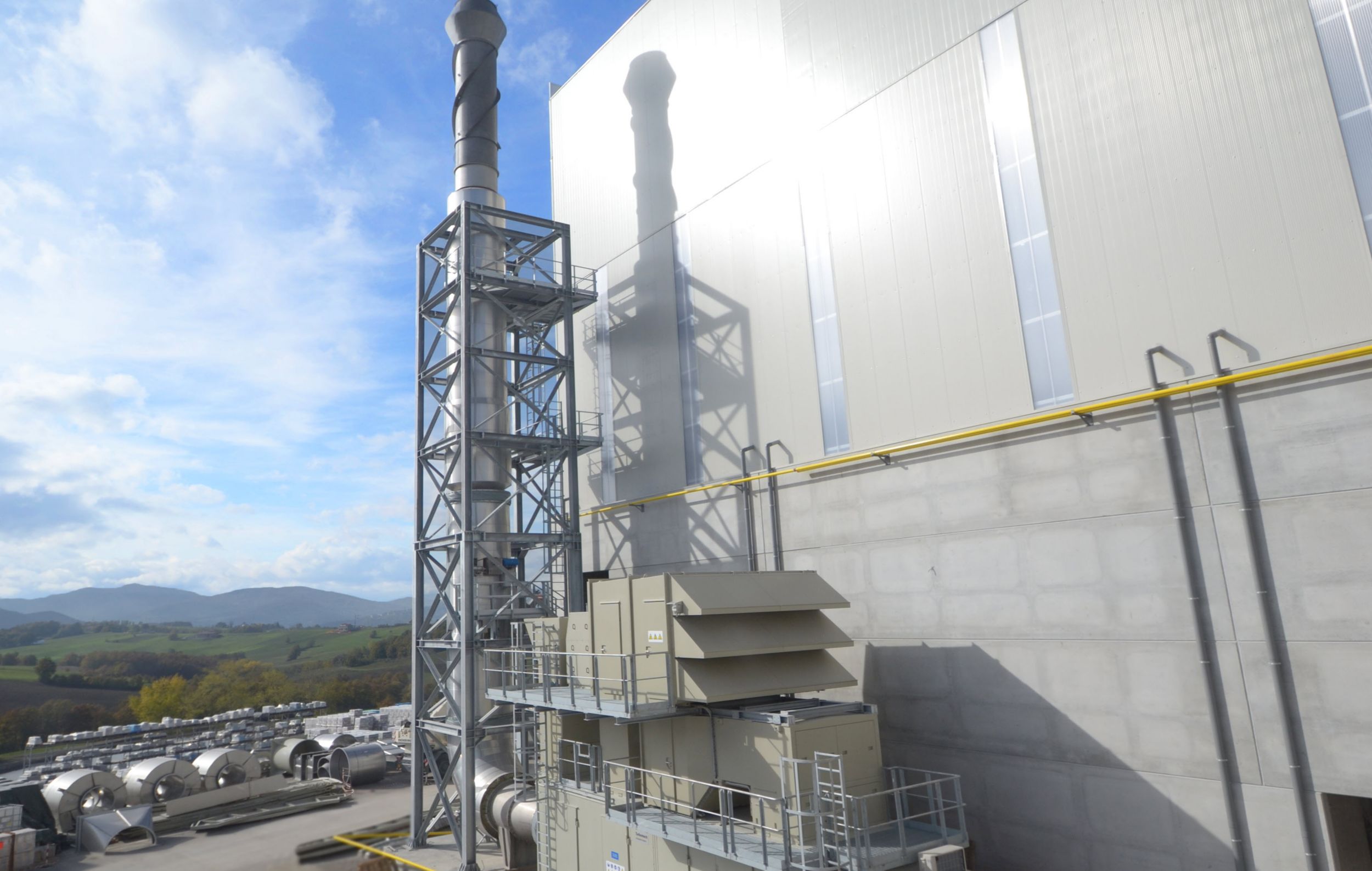

Years of Experience Powering Your Ceramic Needs

Solar has more than 100 units connected to spray dryers in several ceramic manufacturing sites. Solar’s experience in direct drying raw materials and composites, and the clay atomization process, has contributed to ceramic industry cost savings, emissions reduction and energy consumption.